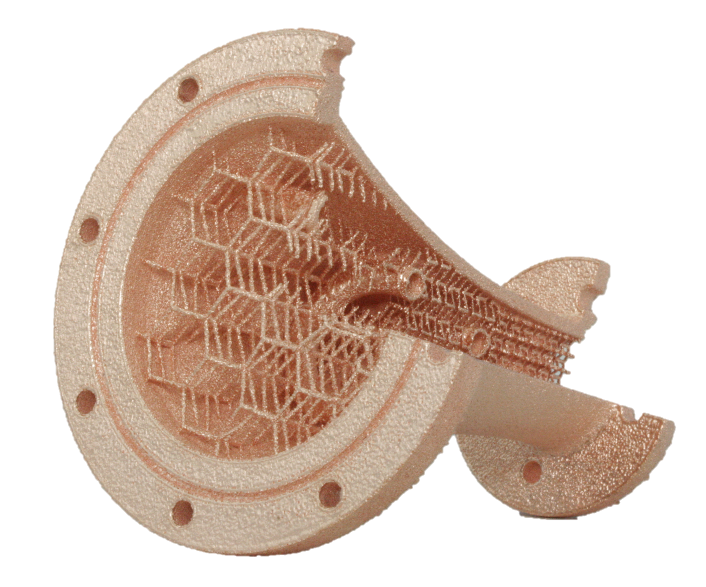

Selective electron beam melting (SEBM) is an additive manufacturing technique for producing metal parts from a powder bed. For producing complex three-dimensional parts, the metal powder is melted layer by layer with an electron beam in high vacuum. So far, copper is not regular used in additive manufacturing. Based on the high potential catalytic activity and the good thermal conductivity, the material copper draws interest for process engineering applications. As part of the current DFG project, a structured reactor based on copper material should be printed in the cooperation of ZMP (Joint Institute of Advanced Materials and Processes) and CRT (Institute of Chemical Reaction Engineering). The structured reactor with integrated catalyst should be optimized in terms of heat- and mass transport.

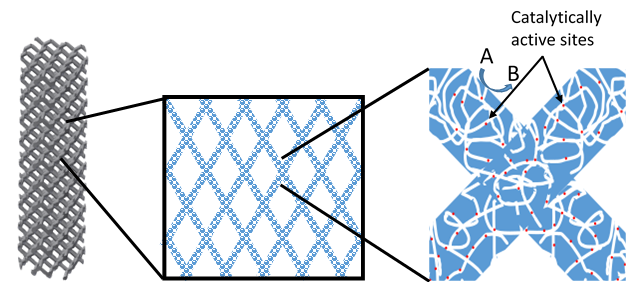

State of the art is to functionalize an inert three dimensional carrier structure by coating with the active material. This procedure involves several process steps (multiple coating, calcination, catalytic activation). In addition, possible problems with the long-term stability of the coating and the comparatively low loading with active catalyst per structure volume are avoided by a newly developed leaching process.

Based on the principal of Raney®, aluminum should leached selectively out of a copper-aluminum alloy to produce nanoporous copper. In this project, a structured CuAl structure is selective leached. Depending on the leach deep, the structured material consists of complete active material. The goal is to produce a highly active and stable structured reactor by optimizing the SEBM process for the production of the CuAl structures and the subsequent leaching process.