Increased value added from biogenic raw materials by selective hydrogenation of biobased platform chemicals

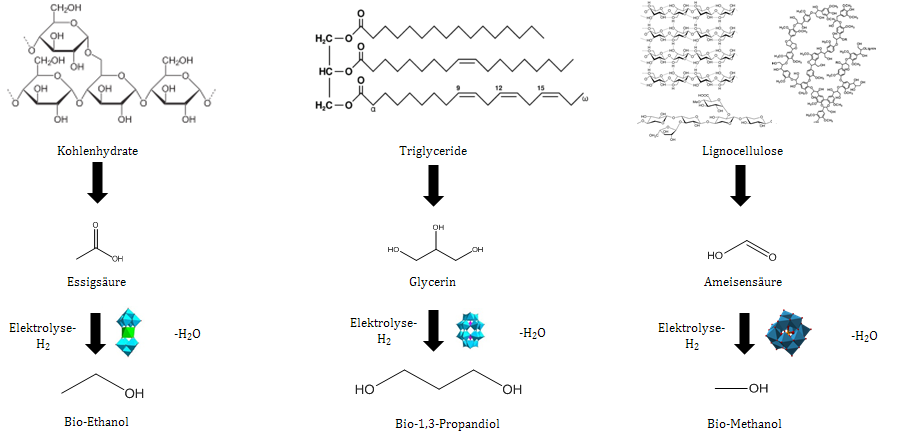

In order to increase the material value added from biomass, which is the only renewable carbon source available, secondary energy sources derived from biomass are converted into higher-quality platform chemicals by hydrogenation in the proposal research project. For this purpose, formic acid from the Erlanger OxFA process, acetic acid from a thermo-chemical or enzymatic conversion of biomass as well as glycerol as a by-product of biodiesel production in combination with renewable hydrogen from water electrolysis are hydrogenated to bio-methanol, bio-ethanol or propanediol. Various polyoxometalate structures should be used as selective hydrogenation catalysts for the production of these biogenic alcohols.

Scheme 1 shows the respective reaction pathways for the production of biogenic alcohols from different biomass composition. In a first reaction step, biogenic acetic acid from carbohydrates is hydrogenated selectively to bio-ethanol. The ethanol produced in this way could then be produced entirely sustainable with the aid of renewable excess electricity and biomass. It can be referred to as bio-ethanol.

Starting from triglycerides from energy crops such as oilseed rape or sunflower, biodiesel is nowadays produced on a large scale. It is achieved by transesterification of mostly vegetable oils with methanol. Glycerol is obtained as a by-product. The selective catalytic hydrogenation with hydrogen from the electrolysis of water with a renewable excess stream provides a promising perspective on the value added from glycerol. Propanedioles are industrially interesting raw materials. They are used in a variety of applications such as food industry, as solvents for dyes and flavors, as moisturizers for tobacco, in cosmetics, as components of brake and hydraulic fluids, antifreezing agents, lubricants in refrigerators, solvents for fats, oils, resins, waxes, dyes, etc.

Lastly, starting from biogenic formic acid, a further homogeneous hydrogenation is taken place with regenerative hydrogen to biomethanol.

This project has been funded since July 2016 by a start-up funding from the Universitätsbund of the FAU Erlangen-Nürnberg.