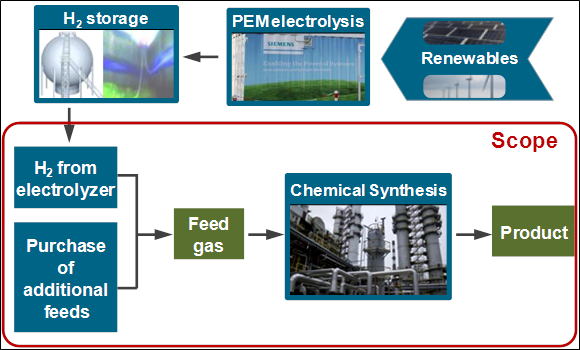

In future energy systems a time dependent deviation between power generation and demand is expected due to the implementation of renewable sources. During energy-rich times (sun is shining, wind is blowing) the production of excess electric energy is expected at locations with a high coverage of sun and wind power units. This excess electricity enables the production of hydrogen via electrolysis. Hydrogen can either be used directly or it can be converted to liquid fuels and chemical raw materials. The latter two options enable hydrogen storage and transport whenever there is no hydrogen infrastructure or hydrogen consumer onsite the electrolysis plant.

Since renewable electricity sources are rather distributed and have a smaller power generation capacity compared to fossil plants, today’s chemical synthesis plants do not fit in terms of capacity as they have often been designed for investment cost optimization in world scale size. However, the distributed generation of excess electricity requires the development of future synthesis systems that are smaller in scale (e.g. <100 MW) and allow a more flexible operation (fast load ramps, improved part load behavior, etc.) to adapt their production rate to fluctuating energy sources.

Different synthesis products and hydrogen carriers are discussed in the literature. As possible products for the recovery of hydrogen from local overproduction of renewable energy only liquid fuels are considered since they can be easily stored and transported. In addition, a carbon source has to be identified that can be converted with the hydrogen resulting from the hydrolysis.

In the working group “biomass and sustainable production of platform chemicals” we are dealing with the development of a process for converting hydrogen with a suitable carbon source to form a liquid fuel. This project is carried out in the framework of the “Future Energy System” campus in cooperation with the SIEMENS AG. This procedure should be suitable for a wide range of raw materials and dynamically operable to be adapted to a fluctuating amount of synthesis gas. The obtained product is then available as a sustainable platform chemical. Further information on this project can be found here http://www.campus-fes.com/.