Sustainable production of acrylic acid

Acrylic acid, one of the simplest unsaturated carboxylic acids, has the vinyl group located at the α-carbon (prop-2-enoic acid). It is a colorless and clear liquid with a characteristic smell. Acrylic acid along with its salts and esters (acrylates) are key basic materials for the superabsorbent, adhesive, and paint/surface coating industries. Materials based on acrylic acid or its derivatives have transparency, good adhesion, elasticity, and stability with respect to air and moderate heat.

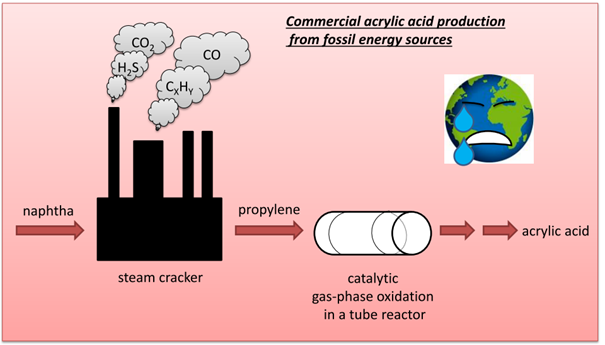

Conventionally, acrylic acid is manufactured by a catalytic two-step gas-phase oxidation of propylene with a total worldwide productivity of more than five million tons per year. One main disadvantage of this route is the total dependency on non-renewable fossil resources.

Nowadays, efforts to reduce atmospheric CO2 emissions and the increasing concern about the availability of fossil raw materials has led the chemical industries to search for alternative bio based feedstock for acrylic acid production.

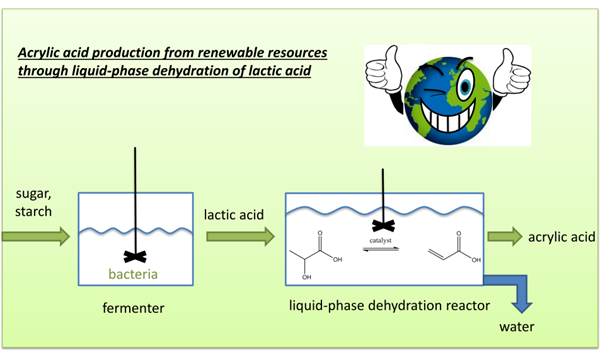

For this reason that we are investigating the use of renewable, biomass feedstock as a basis for a sustainable and large-scale production process of “green” acrylic acid.

Lactic acid (2-hydroxypropanoic acid) can be produced biotechnologically via fermentation of carbohydrates (sugar, starch) and can further be catalytically dehydrated to acrylic acid. Lactic acid produced by fermentation combines low production cost and minimization of oil consumption. Therefore, it represents an attractive and environmentally friendly alternative as feedstock for the production of bio acrylic acid.