E2Fuels: Development of a single-stage process for methanol synthesis from anthropogenic CO2 and renewable hydrogen via in-situ product sorption

Renewable energies generate electricity independently of the power demand. Depending on the weather conditions, there is an over- or underproduction of electricity. In order to adjust electricity generation to demand, buffers are needed that can store excess electricity and feed it back into the grid in times of a positive residual load.

One possibility to store energy that is considered promising is the electrolysis of water, in which hydrogen is formed. With a value of 33.3 kWh kg-1, hydrogen is the molecule with the highest gravimetric energy density. However, its volumetric energy density of 0.003 kWh L– 1 is low due to the gaseous state of hydrogen at ambient conditions. Consequently, storage of gaseous hydrogen is linked with high pressures and costly safety measures due its explosive nature. An option to overcome this limitations is the further processing of hydrogen into fuels and platform chemicals. In a techno-economic evaluation in cooperation with Siemens AG methanol was identified as a chemical energy carrier showing technological and economic advantages over other products. [1]

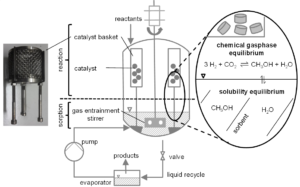

To convert hydrogen from electrolysis into renewable methanol, the use of anthropogenic CO2 as carbon source is sought. Methanol synthesis with CO2, however, is strongly limited by the equilibrium of the reaction, reducing single-pass conversions and inducing high energy costs for gas recycling. Therefore, the concept of in-situ product sorption is followed in the E2Fuels project. In this concept, the equilibrium is shifted to the product side by removing the synthesis products from the reaction chamber with the help of a liquid sorbent, which is situated in the bottom part of the reactor (see Figure 1). The sorbent is continuously circulated to regenerate in a distillation column, where the low boiling products are stripped. [2]

E2Fuels is a joint project funded by BMWi focused on the synthesis of different e-fuels like hydrogen, methanol and OME and their mobile, maritime, and stationary applications. Within the scope of the project the technological, economical, and ecological aspects of the whole process chain are studied by a consortium of research groups and industrial partners (f.e. Siemens AG, MAN SE) to develop a roadmap for the introduction of e-fuels to the market.

[1] A. Tremel, P. Wasserscheid, M. Baldauf und T. Hammer, „Techno-economic analysis for the synthesis of liquid and gaseous fuels based on hydrogen production via electrolysis“, International Journal of Hydrogen Energy, Jg. 40, Nr. 35, S. 11457–11464, 2015, doi: 10.1016/j.ijhydene.2015.01.097.

[2] J. Reichert et al., „Shifting the equilibrium of methanol synthesis from CO2 by in situ absorption using ionic liquid media“, Sustainable Energy & Fuels, Jg. 3, Nr. 12, S. 3399–3405, 2019, doi: 10.1039/C9SE00494G.